Water jet cutting of sensitive foods, such as cutting patterns into bread dough, places high demands on precision, hygiene, and process speed. Our new development sets new standards in this area: a specially designed 2/2-way coaxial solenoid valve made of stainless steel enables precise cuts with a water jet—hygienic, efficient, and adaptable to various production requirements.

Innovative compact valve technology for precise cutting of clean patterns

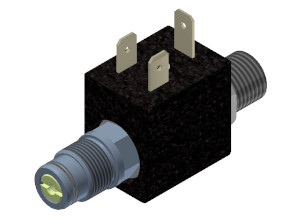

At the heart of this new development is a compact coaxial solenoid valve with an integrated check valve to prevent dripping and an integrated nozzle. The extremely fast opening and closing within a few milliseconds produces a precisely metered water jet that places the cuts cleanly. The check valve prevents unwanted dripping, which ensures product quality and keeps the system clean.

Fine jet nozzle for clean cut edges

The fine jet nozzle used ensures an even, concentrated water jet. Thanks to the choice of different nozzle sizes, the jet can be optimally adapted to different types of dough and cutting requirements. The cutting depth is flexibly adjustable, offering a high degree of process control – from fine surface cuts to complete separations.

Customizable process parameters

The new development enables operation at pressures of up to 150 bar initially (on request). Depending on requirements, we can individually adjust the pressure, nozzle size, and cycle frequency to achieve optimal results with minimal water consumption.

Increased productivity in food production

The extremely short switching times of our solenoid valves enable us to increase the cycle rate of the system, which means a significant increase in productivity. Our customers can process more dough pieces in less time without compromising on cutting quality.

Conclusion:

With this new development, we are raising the bar in water jet cutting of food products. The combination of a fast-acting 2/2-way coaxial solenoid valve, a fine jet nozzle, variable pressure adjustment, and a check valve to prevent dripping enables precise, clean, and highly productive processing—ideal for modern bakeries that value consistent quality and efficient processes.