Questions and Answers

What does the abbreviation BFS mean?

BFS means Bavaria Fluid Systems.

What does BMV mean?

BMV means Bavaria Fluid Systems Magnetventil or translated into English: Bavaria Fluid Systems solenoid valve.

What does BMV6 mean?

BMV6 means Bavaria Fluid Systems solenoid valve series 6. Our inline solenoid valves with nominal diameters 1.0 mm, 2.0 mm and 2.8 mm are combined in this series.

What does BMV7 mean?

BMV7 means Bavaria Fluid Systems solenoid valve series 7. Our inline solenoid valves with nominal diameters 3.0 mm, 4.0 mm and 5.5 mm are combined in this series.

What is the duty cycle of BFS inline solenoid valves?

Unless otherwise specified, the duty cycle of our solenoid valves is 100%.

Can BFS inline solenoid valves be used for slurries?

That depends on the size and properties of the solid bodies in a slurry. Our solenoid valves are basically designed for clear liquids and for gases. If solid bodies are present in a liquid, the function of the valve can be impaired depending on their size. If the solid bodies in the slurry are sufficiently small, our inline solenoid valves could be suitable for this application. Please contact us. We will be pleased to advise you.

How quickly do BFS inline solenoid valves open and close?

The interval for opening and closing our solenoid valves depending on the nominal diameter, compression spring, coil power as well as viscosity and pressure of the fluid is in the single-digit millisecond range. This is so short that our valves can produce razor-sharp images from drops of water.

What is the operating life of BFS inline solenoid valves?

The operating life of our solenoid valves is more than 12 million switching cycles. Many of our valves have been used by our customers for more than 10 years and have completed more than one billion switching cycles during this time.

Up to what maximum pressure can BFS inline solenoid valves switch?

The so-called switching pressure depends, among other things, on the power of the solenoid coil and the nominal diameter of the solenoid valve. The smaller the nominal diameter for the same coil capacity, the higher the switching pressure. The actual maximum switching pressure can be taken from the respective data sheet.

Are there normally closed (NC) and normally open (NO) BFS inline solenoid valves?

Yes. We offer both variants. Please contact us so that we can offer you the best possible solution.

Why does my BFS inline solenoid valve no longer switch after prolonged operation with tap water?

If the solenoid coil is energized and the valve is open, lime can precipitate from the water at low tap water flow velocities (e.g. before reverse osmosis systems) and deposit inside the valve. This normal process is also known in coffee machines. For this reason, a solenoid valve through which tap water flows should be periodically cleaned of limescale at least every two months either with citric acid or with a commercially available descaler and then rinsed with water. Please check beforehand whether the seals and metals are resistant to the descaler.

Are BFS inline dosing valves also available?

Yes, our inline solenoid valves can be clocked with appropriate electronics, for example with pulse width modulation, so that the desired quantity of a gas or liquid is made available. Due to the very short switching times of our solenoid valves, even small quantities of several millilitres can be dosed very accurately. Please contact us so that we can offer you the best possible solution.

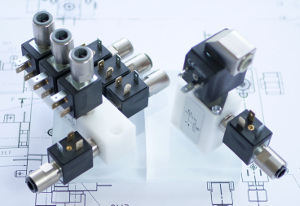

How is a BFS inline solenoid valve mounted sealingly?

Our solenoid valves are available in a modular system with various connectors. This makes it possible to configure the valves ex works according to your requirements so that they can be installed very easily and sealingly in the respective hydraulic or pneumatic system. Unsafe adapters and aids are no longer required.

Are your solenoid valves gas-tight?

Yes. We test each of our solenoid valves for internal and external gas tightness before delivery. In the case of internal tightness, the sealing of the valve seat is checked. For the external tightness, we check the sealing of all O-ring seals.

Are BFS inline solenoid valves suitable for liquids and gases?

Yes, our valves prove their worth both with liquids such as oil, water or beer and with gases such as shielding gases in welding technology.

Do you offer explosion-proof inline solenoid valves?

Yes, we offer explosion-proof inline solenoid valves according to ATEX and IECEx for use in potentially explosive environments. Please contact us. We will be pleased to advise you.